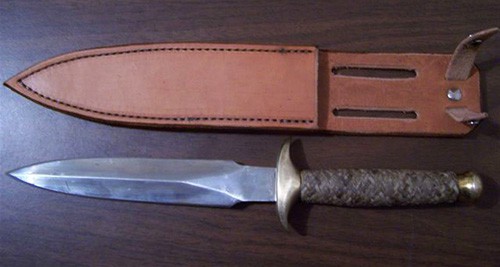

Handmade hunting knives can rival some of the best hunting knives money can buy, providing you a reliable tool that will be there when you need it most and that fits your hand perfectly. But with a handmade knife, you also get the satisfaction of getting to know that knife intimately as it slowly takes shape beneath your hands from a rusty old file, the leg bone of that buck you took last fall, or maybe from a Damascus steel blade blank you bought to finally make your dream knife.

There are a wide variety of materials you can use to make your own hunting knife, not just for the blade but for the handle, too. As such, there are also considerable variances in how to make a hunting knife.

We’ll take a look at some of the many options that are available to you, both in materials and methods. From there, we’ll take a good look at how to make a hunting knife using a partial tang blade blank and a deer antler so you can get started making a one of a kind hunting knife right away.

This is, by far, one of the simplest methods as you won’t have to mess around with forging and tempering, nor will you require power tools. In the end, you’ll have a sturdy knife with a comfortable grip that just needs a small amount of sharpening before you can take out into the wilderness with you.

Different Ways to Make a Hunting Knife

While we’ll be detailing instructions on making a hunting knife using a premade blade blank below, there are a number of different methods that can be used to make a sharp and reliable knife. The major differences among them will be the materials used and, thus, the complexity of the process.

Simpler methods will, naturally, require fewer tools and are often more primitive -though that should not be used as an indicator of their quality or performance. More complex methods will require a greater number of specialty tools and techniques in order to produce a finished product, but these finished knives may easily rival any you find in your favorite hunting store.

Handle Types

When it comes to determining what material to use for the handle of your homemade hunting knife, there are so many durable and unique materials to choose from.

Essentially, what to use to make a handle is limited only by your own level of creativity. Of course, the type of blade you’re making will influence what materials are best suited to your handmade knife project. For example, if you want to use a deer hoof you will have to use a partial tang blade. A full tang or through tang simply will not work. However, if you want to use stone or gemstones for the handle, you’ll have greater levels of success if you make scales and affix them to a full tang.

To affix your handle to your knife blade, you’ll need a strong epoxy, clamps, and possibly pins (usually made of brass). Pins are used with full tangs and partial tangs, though they are not a requirement. They’re an additional way to secure the scales to the tang for the handle. If you do use pins, you’ll still want to use an epoxy to bind the scales to the tang.

Unless you have experience making knives, a through tang blade isn’t recommended as this is the most difficult to and intensive when it comes to the handle. A through tang runs through the entire length of the handle and protrudes out the end. That end is then screwed into a threaded pommel. It is the use of epoxy and the screwing on of the pommel that secures the handle to the blade.

A full tang blade will require you to make scales for the handle, one for each side. This allows you to accomplish some more artistic designs, as you could stack different types and colors of wood or stone along the handle for a unique design. Of course, you can also just stick with one piece of material, cutting and shaping it, and then sanding it smooth so it perfectly so it fits your hand.

If you’re making scales out of wood, using a tight grained hardwood will create a more durable handle. Ideally, you want to cut your handle scales a little larger than your design calls for and then allow them to dry for 6 months to a year. This is to ensure that any moisture in the center of the wood has a chance to come out. Wood that still contains moisture in it will eventually shrink, causing it to potentially crack and split around the rivets. However, working with stabilized wood helps to prevent this, as well as swelling that can come from the knife getting wet or enduring high humidity. Choosing stabilized wood for your handle will also allow you to get started right away once you have all the materials gathered.

Knapping

Stone tools are the most ancient tools known to man, with the oldest stone knife being 1.4 million years old. This method can be used to make a knife out of obsidian, flint, chert, or other types of stone that break in a similar fashion. The stone is shaped into a blade by strategically “hammering” the stone in order to cause small pieces to flake off. As pieces are flaked off, a sharp edge is thereby produced.

Some hunting and outdoor supplies sell complete stone knapping kits that will allow you to make your own stone knife at home. You can also purchase a selection of flint stone pieces that can be used to make knives, arrow heads, or even gun-flints.

Stone blades can be left as is and used or you can make a handle for them using wood, antler, or even bone. An epoxy or natural bonding agent would be necessary to attach the handle. You can use rawhide to create a better grip around a wood handle or use it similar to a guard to hide the meeting point between the blade and the handle.

Bone Blades

Primitive methods of creating a blade from bone often involved shattering the bone and then sharpening the resulting sharp edge. However, you can make a beautiful blade using a leg bone from a larger game animal. Choose a bone that has a nice flat side to it. Usually, a leg bone will be flatter along one side while being quite round on the other. Using a table saw, cut the bone in half lengthwise so that the flat side of the bone and the round side are separated from each other.

The flat length of bone will then be shaped using a belt sander. You’ll want to hold the entire length of the bone to the sander in order to make the bone flat. Then, use the sander to slowly shape the blade. From there you can begin to form the edge of the blade with the sander, finishing the edge with sandpaper.

For the handle, you can leave the bone as is, with some minimal shaping on the sander to make it more comfortable to hold. You can also wrap it in rawhide for a softer grip, or make a handle using wood or antler. If you choose to make an antler handle, the process will be much the same as we’ll outline below.

Shaping and Reshaping Metal

Should you prefer a steel blade and want to shape the blade yourself, be forewarned that you set quite the project before yourself. This is a project for which you’ll require a few tools, such as a hacksaw, jeweler saw (and several blades), or jigsaw, as well as a circular sander, an angle grinder, or, at least, a variety of good files. You’ll also be hardening and tempering the metal, so you’ll need tongs and either a coal forge, gas forge, or blow torch (this only works for small blades -you need to maintain heat which you can’t do for a large blade with a blow torch); not to mention tempering liquid such as oil.

There are a few options when it comes to blade material. Generally, carbon steel is a great choice as it is easier to work with and strong; stainless steel requires a more complicated tempering process. A thickness of between 1/8 of an inch and ¼ of an inch is a good standard.

For the actual piece of metal, you can reclaim and shape an old file, saw blade, or even the leaf spring from a car. There are also blade blank billets that you can purchase to reshape, such as this ladder patterned Damascus steel billet by Poshland Knives. It measures 10.4 inches long and 2 inches wide, giving you plenty to work with for a full tang hunting knife. It also measures 5.07mm thick (1/5 of an inch) that would provide you with a solid and very durable knife. Damascus steel is known for its strength and ability to hold an edge, as well as distinctive pattern caused by the forging of this steel.

The exact method for shaping metal into a knife blade far exceeds the scope of this article, however, there are a lot of resources available should this be something in which you’re interested. Be prepared for an intensive process that may try your patience but, should you persevere, will produce a beautiful knife that will serve you well for many years to come.

Making a Hunting Knife From a Blade Blank

How to make a hunting knife doesn’t need to be overly complicated, though. You can simplify the process by starting with a pre-made hunting knife blade. These are called blade blanks and they’re available in a huge selection of different styles and sizes of blades, as well as in different types of steel. We previously looked at a number of hunting knife blade blanks in different styles and steel types. This is a great place to start when looking for a blade blank for your handmade hunting knife.

What Size Is Best?

When it comes to determining the right size of the blade and handle, there truly isn’t a right or wrong answer. For the blade, it should be long enough to be functional but not so long that you never use half the blade length. A good functional blade length -though, admittedly, not so impressive- is about four inches. You may want to go a little bit shorter in order to comply with local everyday carry laws so you can keep your knife on you all the time. However, you may also want to go a little bit longer to provide a longer stroke. It’s really up to your own personal preference and how exactly you intend to use the knife. If you’ll use it primarily for skinning, then you could get away with a blade as short as 3 ½ inches -so long as it has a nice deep belly on it to allow for longer strokes and more natural movements.

For this reason, knowing how you’ll use the knife should be the first consideration, as you can then focus your search for the perfect blade blank based upon sizes available within a certain style.

As for the handle size, this will be dependent upon your hand size. As you’ll be working with antler for the handle, you may choose to work with the crown end, as it is thicker and provides a nice solid grip, or a thicker inner curve that will better fit the contour of your hands. The exact antler that you have and its shape will also determine what section of the antler you should use and how large you can make it.

Materials Needed

In order to make this knife, you’ll need a few simple tools and supplies. These should be easily gotten from any hardware store if you don’t already have them lying about your garage or workshop.

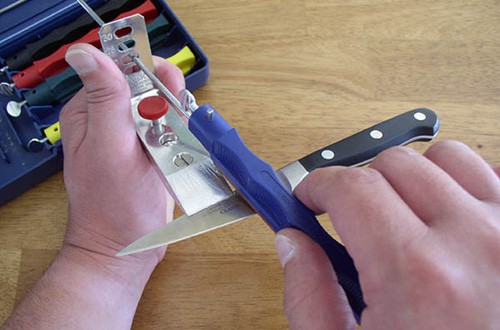

As you’ll be working with a blade blank, the bulk of this project is in making the handle and then attaching it to the blade. You may need to follow up with sharpening the blade to get your blade as sharp as you prefer, though most blade blanks do come at least semi-sharp.

Antler is a great material for handmade knife handles as you can work with the crown end for a very distinctive look, or work with a thicker inner curve, lightly sanding and oiling the antler for a sleeker look. It’s also a great way to put that quite trophy worthy set of antlers you’ve been keeping to good use.

The ideal section of antler to use for the handle will be the thickest section that is below the first fork and the crown (where it connects to the deer’s head). The next ideal section is from between that first fork and the second fork (as it will, generally, be thicker).

With a pencil, mark where the antler will need to be cut and then cut along that line using your hacksaw. Next, you’ll need to hollow out the center of the antler using your drill. Be sure that it’s hollowed deep enough to accommodate the length of the tang and wide enough to allow room for the epoxy and the width of the tang.

NOTE: Be sure to wear safety goggles and a dusk mask while cutting and drilling the antler. That dust is nasty and you don’t need to get it in your lungs or eyes.

Place the epoxy or natural glue into the hollow of the antler and then insert the tang. Wipe off any excess epoxy and allow the knife to dry. This step can take a few days in order for the epoxy to fully dry. Once dry, your handmade hunting knife is essentially done. If you used an inner antler piece, you may want to sand it lightly in order to smooth the end, following up with a light coat of oil or carnauba wax to afford it some extra protection.

You can also finish off the knife with rawhide, wrapping it around the meeting point of the blade and antler. While this does offer some additional securing of the handle and the blade, it is mostly aesthetic. The rawhide will need a day or so to dry but then you can immediately begin using your new custom hunting knife.

There’s a lot of information to consider when looking at how to make a hunting knife. There are a variety of materials that you can use -from premade blade blanks and handle scales to reclaimed metal that you shape and forge yourself- and appropriate methods and techniques that go along with each type of material. But, even the simplest method of making a hunting knife can be a satisfying project, providing you with a great looking one of a kind knife that you can take pride in knowing that you made yourself. Beginning knife makers will be off to a great start following our instructions on making a knife with an antler handle and will have a better idea of what’s in store for them should they choose a more complicated method to make next.

In terms of ease of construction, after making the knife outlined above, you may enjoy making a full tang hunting knife with hardwood scales. You can start with a knife blade blank and focus your energies and creativity on designing and shaping the perfect handle to fit your hand. This project is a bit more intensive, as you’ll need to work with a jigsaw, but from there you’ll be able to work your way up to making the blade by hand, too.

How to Make a Hunting Knife Conclusion

Regardless of what method you use, a handmade hunting knife is something to be proud of and a functional tool that can easily outlast you if made properly. Knowing how to make a hunting knife is a great skill to add to your self-sufficiency skill set and another way that you can make some money to support an off-grid wilderness lifestyle.